Abstract: Rigid PVC has disadvantages in processing such as brittleness and poor low temperature toughness, our product ADX-600 acrylic impact modifier(AIM) can perfectly solve such problems and has better performance and higher cost performance than the commonly used CPE and MBS modifiers. In this paper, we first introduced ADX-600 AIM, and then compared ADX-600 AIM with chlorinated polyethylene (CPE) and MBS in various aspects, and combined with specific applications in several PVC pipe types, we objectively analyzed and concluded that ADX-600 AIM has better overall performance in PVC pipe fittings.

Keywords: Rigid PVC, Pipe, ADX-600 AIM, CPE, MBS

Introduction

As one of the products of technological development, PVC pipes can be found in everyday life. PVC pipes are well received by the engineering community for their light weight, corrosion resistance, high pressure strength and safety and convenience. In recent years, under the driving force of the rapid development of the domestic economy, especially the support of the relevant national policies, the production and application of PVC pipe has made significant development, PVC pipe production has accounted for more than 50% of the total output of plastic pipes, widely used in industry, construction, agriculture and many other industries. Due to the rapid development of PVC pipes in China, the demand for PVC impact modifiers has also increased. Our product ADX-600 AIM toughened PVC pipe has excellent mechanical properties. The water supply pipe has the advantages of health, safety, durability, energy saving, environmental protection and economy, etc. It has a wide range of applications, mainly including underground pipeline networks for water supply, water supply delivery systems in civil and industrial buildings, medical, chemical and beverage industry delivery systems, public places and garden irrigation systems, etc.

I. Introduction of ADX-600 AIM products

Property

ADX-600 impact modifier is a free-flowing powder.

| Property | Index | Unit |

| Physical Appearance | White Powder | |

| Bulk Density | 0.4-0.6 | g/cm³ |

| Volatile | <1.0 | % |

| 20 Mesh Screening | >99 | % |

*The index just represents typical results which are not considered as a specification.

Key Attributes

●Good impact strength

●Reliable weather resistance

●Improve plasticizing efficiency effectively

●Low post-extrusion shrinkage or reversal

●Excellent processing properties and high gloss

Rheology and Handling

ADX-600 impact modifier exhibits faster fusion characteristics than competitive products, which allows for economic benefits by reducing the dosage levels of processing aids and internal lubricants in the formulation.

Impact strength

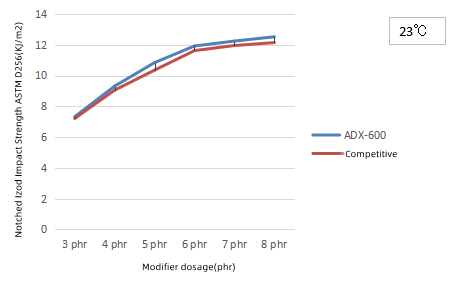

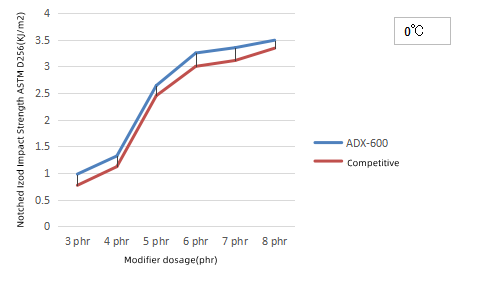

ADX-600 impact modifier provides good impact improvement at room temperature and 0°C.

The efficiency of ADX-600 is much higher than competitive products.

II. Comparison of the performance of ADX-600 AIM with different modifiers

Our product ADX-600 is a core-shell acrylate impact modifier made by emulsion polymerization. It is proven that 3 parts of ADX-600 + 3 phr CPE can be used instead of 9 phr CPE in PVC pipes; ADX-600 can be used in equal parts instead of MBS. In conclusion, ADX-600 AIM has better overall performance and the resulting products have better mechanical properties and are more cost-effective. The following is a comparative analysis of the performance of different impact modifiers in different pipe types.

1.Rigid polyvinyl chloride (PVC-U) pipes for water supply

The base material was prepared according to Table 1, and then ADX-600 and CPE and MBS were added, and the performance was tested after the specimens were made by the instrument as shown in Table 2.

Table 1

| Name | Calcium and Zinc Stabilizer | Stearic Acid | PE Wax | Calcium Carbonate | PVC(SG-5) |

| Phr | 3.5 | 0.1 | 0.2 | 8.0 | 100.0 |

Table 2

| Item | Test Method | Unit | Technical Index(CPE/9phr) | Technical Index(ADX-600/3phr + CPE/3phr) | Technical Index(ADX-600 /6phr) | Technical Index(MBS/6phr) |

| Appearance | Visual Inspection | / | Smooth inner and outer walls of the specimen without bubbles, cracks, dents and other problems, with uniform color and luster | |||

| Vicat Softening Temperature | GB/T8802-2001 | ℃ | 80.10 | 82.52 | 81.83 | 81.21 |

| Longitudinal Retraction Rate | GB/T6671-2001 | % | 4.51 | 4.01 | 4.29 | 4.46 |

| Dichloromethane Impregnation Test | GB/T13526 | % | 20.00 | 15.00 | 17.00 | 17.00 |

| Drop Hammer Impact Test (0℃) TIR | GB/T14152-2001 | % | 5.00 | 3.00 | 4.00 | 4.00 |

| Hydraulic Test | GB/T6111-2003 | / | No rupture of specimens, no leakage | |||

| Connection Sealing Test | GB/T6111-2003 | / | No rupture of specimens, no leakage | |||

2.Rigid polyvinyl chloride (PVC-U) pipes for drainage

The base material was prepared according to Table 3, and then ADX-600 and CPE and MBS were added, and the performance was tested after the specimens were made by the instrument as shown in Table 4.

Table 3

|

Name |

Calcium and zinc stabilizer | Stearic Acid | PE Wax | Calcium Carbonate | PVC(SG-5) |

| Phr | 3.5 | 0.1 | 0.3 | 20.0 | 100.0 |

Table 4

| Item | Test Method | Unit | Technical Index(CPE/9phr) | Technical Index(ADX-600/3phr + CPE/3phr) | Technical Index(ADX-600/6phr) | Technical Index(MBS/6phr) |

| Appearance | Visual Inspection | / | Smooth inner and outer walls of the specimen without bubbles, cracks, dents and other problems, with uniform color and luster | |||

| Vicat Softening Temperature | GB/T8802-2001 | ℃ | 79.11 | 81.56 | 80.48 | 80.01 |

| Longitudinal Retraction Rate | GB/T6671-2001 | % | 4.52 | 4.02 | 4.10 | 4.26 |

| Tensile Yield Stress | GB/T8804.2-2003 | MPa | 40.12 | 40.78 | 40.69 | 40.50 |

| Elongation at Break | GB/T8804.2-2003 | % | 80.23 | 84.15 | 83.91 | 81.05 |

| Drop Hammer Impact Test TIR | GB/T14152-2001 | % | 5.00 | 3.00 | 4.00 | 4.00 |

| Watertightness | GB/T5836.1-2018 | / | No leakage of any specimen | |||

| Airtightness | GB/T5836.1-2018 | / | No leakage of any specimen | |||

3.Corrugated Pipe

The base material was prepared according to Table 5, and then ADX-600 and CPE and MBS were added, and the performance was tested after the specimens were made by the instrument as shown in Table 6.

Table 5

| Name | Calcium and Zinc Stabilizer | Wax Oxide | Titanium Dioxide | Calcium Carbonate | PVC(SG-5) |

| Phr | 5.2 | 0.3 | 2.0 | 12.5 | 100.0 |

Table 6

| Item | Test Method | Unit | Technical Index(CPE/9phr) | Technical Index(ADX-600/3phr + CPE/3phr) | Technical Index(ADX-600/6phr) | Technical Index(MBS/6phr) | |

| Appearance | Visual Inspection | / | Smooth inner and outer walls of the specimen without bubbles, cracks, dents and other problems, with uniform color and luster | ||||

| Oven Test | GB/T8803-2001 | / | No delamination of specimens, no cracking | ||||

| Ring Flexibility | GB/T9647-2003 | / | Specimens are smooth, no rupture, both walls are not detached | ||||

| Ring Stiffness | SN2 | GB/T9647-2003 | KN/m2 | 2.01 | 2.32 | 2.22 | 2.10 |

| SN4 | 4.02 | 4.36 | 4.23 | 4.19 | |||

| SN8 | 8.12 | 8.32 | 8.23 | 8.20 | |||

| SN12.5 | 12.46 | 12.73 | 12.65 | 12.59 | |||

| SN16 | 16.09 | 16.35 | 16.29 | 16.15 | |||

| Creep Ratio | GB/T18042-2000 | / | 2.48 | 2.10 | 2.21 | 2.38 | |

| Drop Hammer Impact Test TIR | GB/T14152-2001 | % | 10.00 | 8.00 | 9.00 | 9.00 | |

| Elastic Seal Connection Sealing | GB/T18477.1-2007 | / | No leakage of any specimen | ||||

III. Conclusion

By comparing the performance of ADX-600 AIM with chlorinated polyethylene (CPE) and MBS in various aspects and combining them with specific applications in several PVC pipe types, we objectively analyze and conclude that 3 phr ADX-600 + 3 phr of CPE can replace 9 phr CPE in PVC pipe; ADX-600 can replace MBS in equal parts. In conclusion, ADX-600 AIM has better overall performance and the resulting products have better mechanical properties and are more cost-effective. In addition, the ADX-600 AIM is suitable for a wide range of applications, including underground water networks, water supply delivery systems in civil and industrial buildings, delivery systems in medical, chemical and beverage industries, public places and garden irrigation systems.

Post time: Jun-19-2022